Ready to build your dream Allegra 24? Download the comprehensive plans directly from the designer’s website. These plans provide detailed blueprints, ensuring a smooth and accurate build process. You’ll find precise specifications covering every aspect of the vessel.

The plans cover hull construction, deck layout, rigging details, and even sail specifications. Expect clear diagrams and instructions, minimizing potential confusion. Thorough material lists are included, assisting you in sourcing the necessary components effectively.

Focus on meticulous preparation before commencing construction. Organize your materials and workspace; this minimizes delays and ensures a high-quality finished product. Consider collaborating with experienced boatbuilders for guidance, particularly if you’re a novice. Forums and online communities dedicated to Allegra 24 owners offer valuable insights and support.

Remember, proper planning equates to a successful build. Review all sections of the plans thoroughly before starting. This proactive approach reduces the likelihood of encountering unforeseen issues. Enjoy the rewarding process of bringing your Allegra 24 to life!

- Allegra 24 Sailboat Plans: A Comprehensive Guide

- Construction Considerations

- Customization Options

- Material Selection

- Resources and Support

- Budgeting

- Finding Allegra 24 Plans Online and Offline

- Analyzing the Allegra 24 Design Specifications

- Interior Layout and Comfort

- Key Design Features: A Detailed Look

- Construction and Materials

- Understanding the Construction Methods for Allegra 24

- Deck and Superstructure

- Interior Construction

- Additional Considerations

- Essential Materials List for Building an Allegra 24

- Step-by-Step Construction Process Overview

- Hull Construction

- Deck and Superstructure

- Interior Fit-Out

- Final Steps

- Engine Installation (Optional)

- Modifying the Allegra 24 Plans to Your Needs

- Cabin Layout Adjustments

- Sail Plan Modifications

- Hull Modifications (Expert Advice Required)

- Remember!

- Material Selection

- Cost Estimation and Budgeting for Allegra 24 Construction

- Labor Costs

- Additional Expenses

- Software and Plans

- Total Cost Range

Allegra 24 Sailboat Plans: A Comprehensive Guide

Download the official plans directly from the designer, Ted Brewer. These plans provide detailed blueprints, including hull shapes, deck layouts, and rigging diagrams. Expect precise measurements and clear instructions.

Construction Considerations

The Allegra 24’s plywood construction demands careful attention to detail. Use high-quality marine plywood and epoxy for a strong, durable hull. Precise cutting and meticulous assembly are paramount. Consider using a professional boat builder if your experience is limited.

Customization Options

While the plans offer a solid foundation, explore customization possibilities. Modify the interior layout to fit your needs. Perhaps you prefer a larger galley or more storage. Adjust the sail plan to suit your sailing style and local conditions. Remember to always check the stability implications of any significant design changes.

Material Selection

Choosing appropriate materials directly impacts the boat’s lifespan and performance. Marine-grade plywood is a must; avoid cheaper alternatives. Select high-quality hardware, paying attention to corrosion resistance. Thorough research before purchasing ensures optimal quality and longevity.

Resources and Support

Join online forums dedicated to Allegra 24 owners and builders. Share experiences, ask questions, and learn from others. This community provides valuable support throughout the construction process. Forums are a great resource for troubleshooting and advice.

Budgeting

Create a detailed budget encompassing all materials, tools, and potential labor costs. Include unexpected expenses. Accurate budgeting prevents financial surprises during construction.

Finding Allegra 24 Plans Online and Offline

Check dedicated boat plan websites like BoatDesign.net or YachtWorld. These often feature archived plans or listings from individuals selling their designs.

Explore online forums like those on Sailing Anarchy or the Yahoo Groups dedicated to specific boat types. Members frequently share resources and may have Allegra 24 plans or know where to find them. Directly asking within the community increases your chances of success.

Search eBay and similar auction sites. Occasionally, original Allegra 24 plans appear. Be cautious, verify the seller’s reputation before purchasing.

Contact the original designer or builder, if possible. Their contact details might be listed on previous sale ads or through online boat-building communities. They may hold the original plans or be able to refer you to someone who does.

Visit libraries with extensive nautical collections. Many hold archives of boat plans, though finding the Allegra 24 might require specific research within their catalog.

Attend boat shows and maritime events. Network with boatbuilders and designers; you may find someone with knowledge of Allegra 24 plans.

Consider contacting yacht clubs or sailing organizations in areas known for Allegra 24 sailboats. These groups might have access to plans or know owners who could provide information.

Analyzing the Allegra 24 Design Specifications

The Allegra 24’s success stems from its thoughtful design choices. Consider its hull: a full-displacement design prioritizing stability and comfortable motion in moderate seas. This translates to a safe and relaxing sailing experience, especially for less experienced crews.

Let’s examine the sail plan. The fractional sloop rig, with its relatively small sail area, makes handling straightforward. This simplicity benefits both novice and seasoned sailors, ensuring easy control even in breezy conditions. The design favors ease of use over extreme performance.

Interior Layout and Comfort

The Allegra 24 prioritizes interior space and headroom. The layout maximizes usable area, providing ample storage and comfortable living space for a small crew. Consider the well-placed cabinetry and thoughtfully designed berths, improving practicality during longer trips.

Key Design Features: A Detailed Look

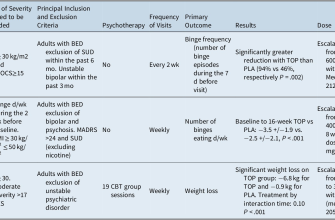

| Feature | Specification | Impact |

|---|---|---|

| Hull Length | 24 feet | Provides a good balance between seaworthiness and manageability. |

| Draft | 4 feet | Allows access to shallower waters. |

| Displacement | Approx. 6,000 lbs | Contributes to stability and comfort in waves. |

| Sail Area | Approx. 260 sq ft | Suitable for a wide range of wind conditions. |

| Engine | Typically a small outboard | Provides auxiliary propulsion when needed. |

Construction and Materials

High-quality materials contribute to the Allegra 24’s durability and longevity. The use of fiberglass construction ensures strength and resistance to the elements. Careful attention to detail in the build process promotes reliability and a long lifespan.

Understanding the Construction Methods for Allegra 24

The Allegra 24 utilizes a robust, proven construction method emphasizing both strength and lightness. The hull is built using a fiberglass composite layup. This involves layering fiberglass cloth and resin, carefully orienting the fibers to maximize strength in critical areas. The process uses vacuum bagging, a technique that removes air bubbles and excess resin, resulting in a strong, lightweight hull. This minimizes weight and maximizes performance.

Deck and Superstructure

The deck and superstructure are also constructed from fiberglass, typically using a similar layup process to the hull. Careful attention is paid to the bond between the deck and hull, often using a robust method of bonding to guarantee a strong, watertight joint. This is crucial for long-term durability and safety.

Interior Construction

Interior construction frequently uses plywood or similar materials for bulkheads and cabinetry. This combination provides structural support, while also offering versatility for customization. The choice of wood and finishing techniques will influence the overall appearance and feel of the boat’s interior.

Additional Considerations

Core Materials: Some Allegra 24s might incorporate core materials, such as foam, within the fiberglass layup. This enhances both insulation and impact resistance. Finishing: The final finish of both the hull and interior contributes significantly to the boat’s aesthetics and protection. Gelcoat provides a durable finish for the exterior, while varnish or paint offers protection for interior wood.

Essential Materials List for Building an Allegra 24

Begin with your lumber. Select high-quality marine-grade plywood, aiming for at least 1/2″ thickness for the hull and 3/4″ for the bulkheads. Expect to need approximately 10 sheets of 4’x8′ plywood. Consider Okoume or similar species for their strength and water resistance.

Next, acquire fiberglass cloth. You’ll require several rolls of biaxial and unidirectional cloth, varying in weight depending on the area of application. Consult the plans for specific weight requirements. E-glass cloth is a suitable and cost-effective choice.

Epoxy resin is the glue that holds it all together. Purchase several gallons of high-quality marine-grade epoxy and hardener. Ensure you have the appropriate mixing cups and sticks for accurate proportions.

Don’t forget the smaller, but equally crucial, components. This includes things like bronze or stainless steel fasteners, various wood screws and bolts, caulking, and paint. You’ll need a generous supply of marine-grade sealant.

For the interior, choose durable materials suitable for a marine environment. This might include marine-grade plywood for cabinetry, foam padding for seating, and waterproof fabrics for upholstery. Plan your interior layout carefully before purchasing.

Finally, consider the deck hardware: cleats, winches, fairleads, and other fittings. Purchase high-quality stainless steel components for longevity. Check your plans for the exact specifications and quantities needed.

Remember to meticulously track your materials as you progress. Accurate record-keeping prevents shortages and ensures a smoother build.

Step-by-Step Construction Process Overview

Begin construction with the keel. Use a strong, durable material like cast iron or a high-quality steel plate. Ensure precise alignment for optimal stability.

Hull Construction

- Construct the frames according to the plans, paying close attention to angles and dimensions. Use marine-grade plywood or fiberglass for strength and water resistance.

- Carefully attach the frames to the keel, reinforcing joints with epoxy and fiberglass cloth.

- Lay the hull planks or fiberglass cloth over the frames, meticulously following the plans. Use quality marine adhesive and sealant at each stage.

- Reinforce stress points, such as the stem and stern, with additional layers of fiberglass.

- Fair the hull’s exterior for a smooth, hydrodynamic surface. This minimizes drag and improves performance.

Deck and Superstructure

- Build the deck using similar techniques as the hull. Ensure a watertight seal.

- Install the cabin top and other deck structures, integrating hatches and portholes. Use quality marine-grade hardware.

- Install the cockpit, paying attention to ergonomics and drainage.

Next, fit the rudder and tiller assembly, ensuring smooth operation and precise control. Install the mast and rigging according to the plans, using high-quality hardware for safety and durability.

Interior Fit-Out

- Install bulkheads and framing for the interior, providing structure and support.

- Install cabinetry and furniture, considering weight distribution and space optimization.

- Install wiring for electrical systems and plumbing for water systems. Use appropriate marine-grade components.

- Finish the interior with paint or varnish, adding a final touch of style and protection.

Final Steps

After completing the interior, perform a thorough inspection. This includes checking all joints and systems for leaks and proper functionality. Conduct a final sanding and finishing. Rigging adjustments complete the process. Remember to test all systems before launching.

Engine Installation (Optional)

If installing an engine, carefully follow the manufacturer’s instructions. Ensure proper mounting, ventilation, and exhaust systems.

Modifying the Allegra 24 Plans to Your Needs

Begin by carefully reviewing the original Allegra 24 plans. Identify areas you want to customize. This might involve altering the cabin layout, sail plan, or even the hull shape (though significant hull modifications require expert consultation).

Cabin Layout Adjustments

- Extend the quarter berths for additional sleeping space. This requires careful consideration of weight distribution.

- Install a larger chart table, potentially incorporating storage solutions beneath.

- Add or remove lockers based on your storage needs. Pay close attention to the impact on stability and weight balance.

- Consider a different galley design. Compact designs maximize space, while larger galleys provide more workspace.

Sail Plan Modifications

Consider your sailing style and typical conditions. You can modify the plans to accommodate:

- A larger mainsail for improved performance in light winds.

- A smaller, more easily handled mainsail for better control in strong winds.

- A different jib or headsail for added versatility.

- Adding a self-tacking jib for easier single-handed sailing.

Hull Modifications (Expert Advice Required)

Significant hull modifications are complex and should only be undertaken by experienced boat builders. Consider these modifications only if you possess the necessary expertise or are working with a qualified professional:

- Adding a skeg or fin keel for improved stability and performance.

- Modifying the rudder for better control in various conditions.

- Integrating a built-in water tank or fuel tank.

Remember!

Always consult with a naval architect before making significant changes to the plans. They can help you assess the impact of your modifications on the boat’s stability, performance, and structural integrity. Careful planning and skilled execution are paramount for a successful project.

Material Selection

Choosing the right materials significantly impacts the final product. Explore alternatives to the materials suggested in the original plans, considering factors like cost, weight, and durability. Consider using sustainably sourced materials whenever possible.

Cost Estimation and Budgeting for Allegra 24 Construction

Begin with a detailed materials list. Price each item from multiple suppliers to find the best deals. Expect to spend around $15,000 – $25,000 on materials alone, depending on your choices (fiberglass cloth, epoxy resin, hardware quality). This range accounts for variations in wood selection (if applicable) and finish levels.

Labor Costs

Factor in labor costs. If you’re building solo, estimate 1000-2000 hours of work. Value your time realistically – a conservative hourly rate helps avoid underestimating your total investment. Alternatively, hiring a skilled boat builder adds significantly to the overall cost; expect $50-$100 per hour, multiplying quickly depending on project duration.

Additional Expenses

Don’t forget ancillary expenses. These include tools (consider renting initially), consumables (sandpaper, paints, etc.), and any necessary molds or patterns. Allocate at least 10-15% of your materials budget for these items. Transportation and storage costs should also be accounted for. Finally, budgeting for unforeseen issues is wise; add a 10-20% contingency fund to address unexpected problems or material price fluctuations.

Software and Plans

The cost of the Allegra 24 plans themselves adds a relatively small amount to the total expense but must be included. Consider any additional software purchases necessary for design adjustments or project management.

Total Cost Range

Therefore, a reasonable budget for building an Allegra 24 should range from $25,000 to $75,000 or more. The higher end reflects professional labor and high-end materials. Careful planning and meticulous budgeting are crucial for successful project completion.